GWV Series “Smart Inverter” Water-lubricated Oil-free Screw Air Compressor

Shipping method: Logistics and transportation

Inventory status: In stock

Feature Details:

It features a self-learning function and intelligent start-stop capability.

It monitors ambient temperature to prevent high-temperature faults caused by excessive environmental heat.

It detects the pressure at the end of the post-processing equipment, effectively eliminating excessively high pressure differentials in compressed air and avoiding waste of electrical energy.

Product Details

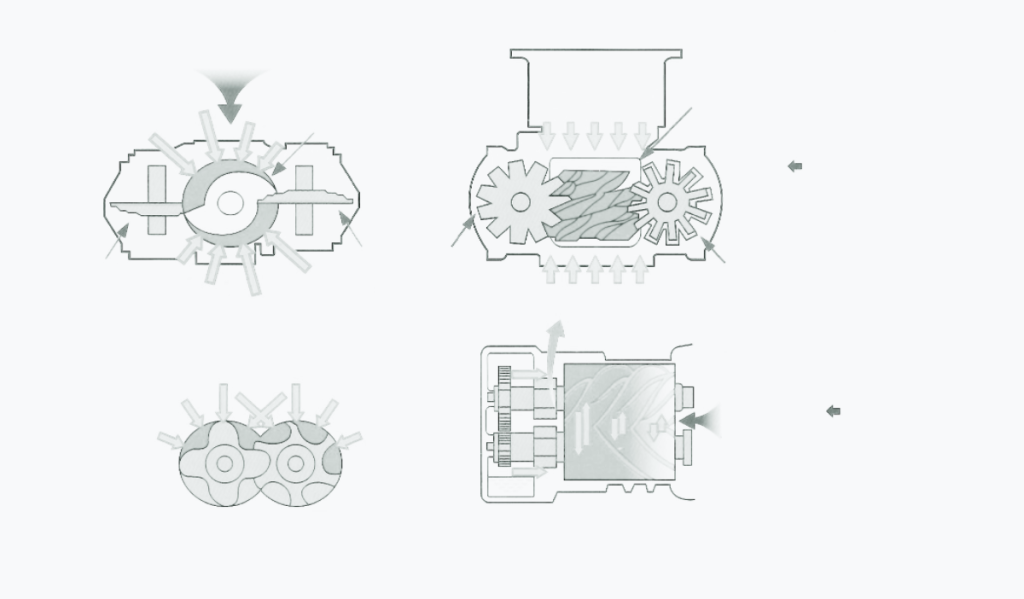

Deduction of mechanical balance

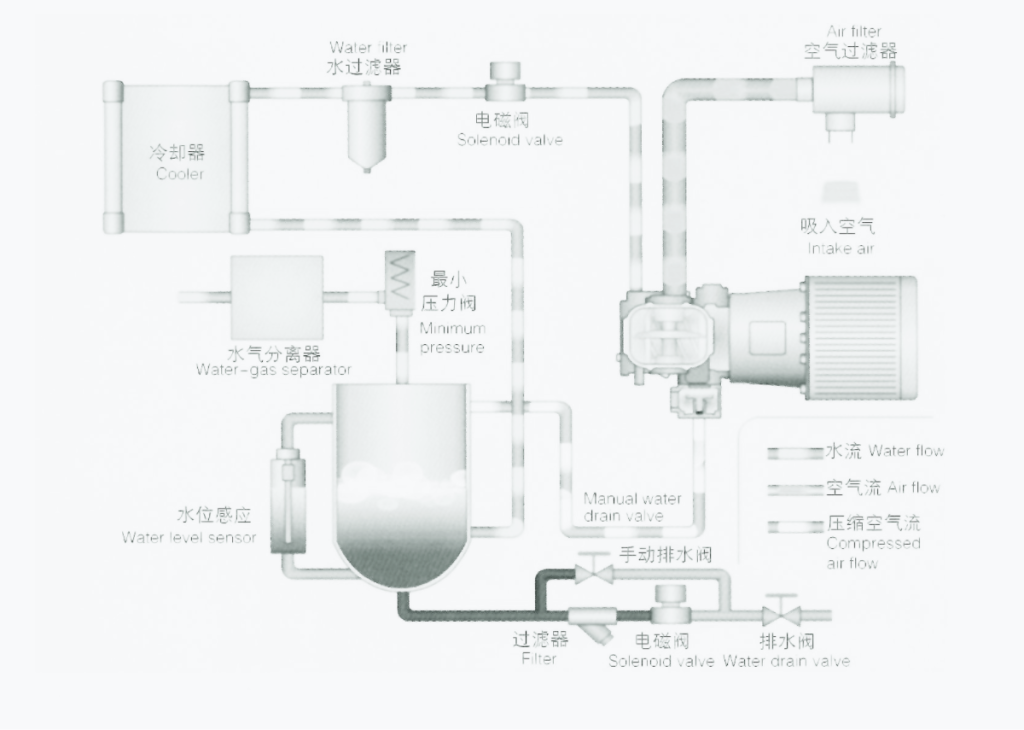

Simple system flow

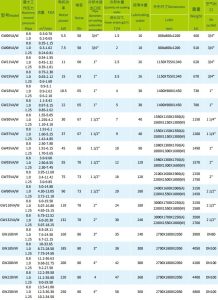

Product parameters

Related Articles:

GW series “smart” water lubricated oil-free screw air compressor

GW Series “Smart” Water-lubricated Oil-free Screw Compressor adopts an advanced intelligent control system for efficient and energy-saving operation. Water-lubrication technology ensures oil-free contamination, and the screw design guarantees stability and reliability. Suitable for various industrial scenarios, it meets customers’ demands for clean and efficient compressed air. It is an ideal choice for environmental protection, energy saving, and high efficiency.

GWL Series “Energy-Saving” Low-Pressure Oil-Free Water-Lubricated Screw Air Compressor

The GWL Series energy-saving oil-free water-lubricated screw low-pressure compressor from Shanghai Grand克林 Group is widely used in industries like textiles, glass, plastics, water treatment, chemicals, and cement, where low-pressure compressors with supply pressures of 0.15-0.4MPa are in demand. It saves over 30% energy compared to conventional low-pressure screw compressors, significantly reducing energy losses.

GWH Series “Smart Inverter” Oil-free Water-lubricated Screw Medium-pressure Compressor

The GWV Series Smart Inverter Water-lubricated Oil-free Screw Air Compressor produced by Shanghai Granklin Group is widely used in industries such as pharmaceuticals, electronics, chemicals, microbial fermentation, blow molding, and pressure testing, as well as in power stations, where medium-pressure compressed air in the range of 1.6 to 4.0 MPa is often required.